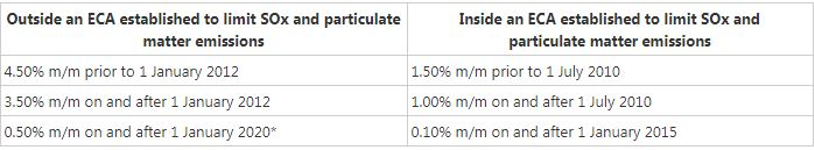

Under the new global cap, ships will have to use fuel oil on board with a sulphur content of no more than 0.50% m/m, against the current limit of 3.50%, which has been in effect since 1 January 2012. Since 1 January 2015 the sulphur limit for fuel oil used by ships in SOx Emission Control Areas (ECAS) established by IMO has been 0.10% m/m. The sulphur content of any fuel oil used on board ships shall not exceed the following limits:

The interpretation of “fuel oil used on board” includes use in main and auxiliary engines and boilers. Ship’s fuel oil injection system is not designed to use low sulphur fuel oil (low viscosity).Fuel viscosity, combustion quality and lubricity are some of the operational challenges. Fuel oil injection components are going to be affected and deteriorated. Therefore fuel oil systems onboard have to be modified. Because of the lower viscosity of Marine Gas Oil, the lubrication requirements of the engine manufacturer may not be met. In most marine diesel engines, the viscosity of the fuel needs to be at least 2.0 cSt. At normal temperature, the viscosity of MGO varies between 1-2 cSt, which means that sufficient engine lubrication can no longer be guaranteed.The viscosity can be improved with additives, but this is relatively costly. However, there is a much more affordable solution. The solution offered by FARAD is simple compact and reliable. MGO cooling unit is required to installed on the fuel oil service system in order to reduce the temperature of the MGO, therefore to increase viscosity. Our MGO cooling unit, chills even to 15 degrees Celsius, so that the viscosity and lubricity meet the requirements of the engine manufacturers.

The interpretation of “fuel oil used on board” includes use in main and auxiliary engines and boilers. Ship’s fuel oil injection system is not designed to use low sulphur fuel oil (low viscosity).Fuel viscosity, combustion quality and lubricity are some of the operational challenges. Fuel oil injection components are going to be affected and deteriorated. Therefore fuel oil systems onboard have to be modified. Because of the lower viscosity of Marine Gas Oil, the lubrication requirements of the engine manufacturer may not be met. In most marine diesel engines, the viscosity of the fuel needs to be at least 2.0 cSt. At normal temperature, the viscosity of MGO varies between 1-2 cSt, which means that sufficient engine lubrication can no longer be guaranteed.The viscosity can be improved with additives, but this is relatively costly. However, there is a much more affordable solution. The solution offered by FARAD is simple compact and reliable. MGO cooling unit is required to installed on the fuel oil service system in order to reduce the temperature of the MGO, therefore to increase viscosity. Our MGO cooling unit, chills even to 15 degrees Celsius, so that the viscosity and lubricity meet the requirements of the engine manufacturers.

FARAD has developed an extended series of MGO Cooling Units which is shown below:

| Model | Heat duty [kW]* | MGO flow (range) [m3/h] |

| MGO-U35 | 31 | 0,5-2,0 |

| MGO-U60 | 54 | 2,0-3,5 |

| MGO-U85 | 77 | 3,5-5,0 |

| MGO-U115 | 101 | 5,0-6,5 |

| MGO-U140 | 124 | 6,5-8,0 |

| MGO-U170 | 147 | 8,0-9,5 |

| MGO-U190 | 170 | 9,5-11,0 |

| MGO-U220 | 194 | 11,0-12,5 |

*MGO Cooling Units inlet temperature 55oC outlet temperature 17oC

Electric panel with PLC system cotrols the following:

Screen display features:

This system provides the following optional features (upon request):

The design and construction are approved by all leading Classification Societies. Certification must be stated at time of order.

3-4 weeks upon order receipt and drawing approval – confirmation.

Tel: +30 2104227410

Fax: +30 2104227303

info@farad.gr

14 Alon Str., Piraeus

GR18540 Greece

FARAD SA Heat Exchangers, since 1979, design and manufacture high quality marine and industrial tubular heat exchangers.

FARAD S.A. Heat Exchangers, since 1979, design and manufacture high quality marine and industrial tubular & gasketed plate heat exchangers.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.